DIY with a goal!

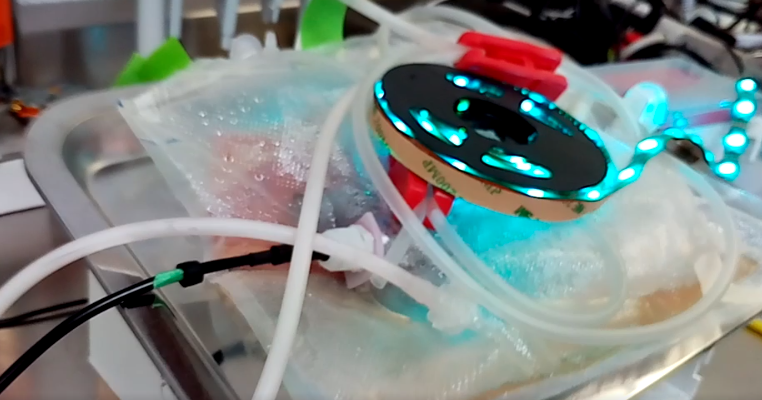

A bioreactor is a chamber that can be used to grow cells in a controlled environment. This specific type can grow both bacterial cells and advance cells due to the type of agitation system. Using a bioreactor allows for control, sterility, quantity and repeatability that is hard to achieve with other means.

One of the areas of this project was reagent production. We succeeded in producing Taq, Pfu and MashUp-RT RT enzymes. We will be adding more reagents to that list.

Of course, a bioreactor like this can be used for countless diverse research projects in so many areas.

Here is a video of several bioreactors with several platform types

A dozen or so of these bioreactors were produced so far and several were used in several labs so far.

We are working on a complete series of video documentation on YouTube and the first part is in here.

First video

Click here to see the bioreactor in action video

Here is an older video with the silicone bag mounted. You might need to download it in order to play it.

See this video to understand how an industrial one looks

JOGL project link. Go there and press on About to find out most details about our project

The Status. Sometimes lagging behind. The Slack progressreport channel is usually updated faster so it's better to join it.

Google Folder for editable documents like Word documents, spreadsheets etc. Contains BOM. Many of these documents are editable so please make sure you don't change things by mistake.

Our Draft Paper. It has some of the sections covered but some are just placeholders

Our Slack channel. Ask for an invitation link and then join it and leave an introduction in the introduction channel detailing what part you are interested in. Unfortunately the invite link expires so we cannot post it in here

Link to our Google drive that has most editable documents

GitHub for the project. Put here code, schematics etc and anything else that needs versions

Areas of the project

Initial UI Design

A document about parts, options and reasons why some specific parts were selected

USE CASES editable document

Similar Devices Research

Look at rows 2, 17 and 19 to understand the principles, the functionality and see different implementations

Open Bioeconomy Lab bioreactor [2]

A re-usable wave bioreactor for protein production in insect cells - very close to what we want [19]

Please read before asking questions as many answers are already present and we want to avoid duplication of information and unnecessary effort.

To understand the project you could either look at our proposal for JOGL project link or read below. The proposal is more complete.

The Status. Sometimes lagging behind. The Slack progressreport channel is usually updated faster so it's better to join it.

Google Folder for editable documents like Word documents, spreadsheets etc. Contains BOM. Many of these documents are editable so please make sure you don't change things by mistake.

Our Draft Paper. It has some of the sections covered but some are just placeholders

Our Slack channel. Ask for an invitation link and then join it and leave an introduction in the introduction channel detailing what part you are interested in. Unfortunately the invite link expires so we cannot post it in here

Link to our Google drive that has most editable documents

GitHub for the project. Put here code, schematics etc and anything else that needs versions

Areas of the project

Initial UI Design

A document about parts, options and reasons why some specific parts were selected

USE CASES editable document

Similar Devices Research

Detecting pathogens like the SARS_COVID2 virus or create treatments like vaccines require reagents (chemicals).

In order to run the reaction you need reagents for each test.

Reagents are expensive and many are unavailable due to demand.

There is an imperious need to create an alternative cheap source for these reagents. There are several labs working on this, notably the free genes that are doing a great job pioneering this. Thanks to them.

The only way to produce those in usable quantities is to use a bioreactor. Commercial bioreactors cost thousands. That does not reflect manufacturing costs. Existing open source designs are not usable, abandoned prototypes or work in progress.

That's why this this is important. A cheap alternative to commercial bioreactors that would cost less than 200$ would solve this and also make possible the rest of the other initiatives.

In a nutshell,a bioreactor is a container with agitated liquid and control of temperature, Oxygen, PH etc.

Things get a little more complicated when you want to grow mammalian cells like for production of antibodies of some more complicated proteins.

And a little bit more complicate because of the need to be sterile and reusable.

This is Not a One Day Wonder or Hip Vaporware project but a project that was started before the pandemic and will be relevant and offer value to humanity after the pandemic too.

Research and work on modules of this project has been started last year before this pandemic so this is not an opportunistic project nor a project started out of the blue with little experience and little chance of success.

We are basing some of this on great work done by other groups in the academia, DIY and industry.

We will be building a wave bioreactor based on several original ideas.

We are not trying to compete with other Open Source initiative but rather collaborate and provide better solutions and implementation where possible.

We will not spend too much time on great looking web pages, formatting a spelling but try to trim the fat ad focus on delivering. So formatting and typos are not going to be a priority. Sorry, no spell checker in this free editing software.

As you can see when looking at the equipment, this is not our first project and our finished projects are functional and in use.

Our first main target is Reverse Transcriptase. That is the first enzyme needed in the CDC virus detection. A reverse transcriptase (RT) is an enzyme used to generate complementary DNA (cDNA) from an RNA template, a process termed reverse transcription. We will of course run RFP bacteria first to test and optimize.